A wrought product is a worked product, primarily produced by hot working, e.g. forging or rolling, although cold working is possible in some cases and is classed as a high energy forming process. Forging is usually used for higher strength applications in comparison to the casting process.

Forging is plastic flow beyond the materials yield strength.

Forging

Forging is one of the oldest forms of metal working processes known to man and is simply illustrated by the blacksmith using a hand held hammer and anvil working the hot metal supported by tongs.

At the other extreme, very precise pairs of dies may be used with hydraulic presses to produce precision finished components.

Forging is often used when strength and toughness are needed from the components. Many basic components, e.g. nuts, bolts and rivets are mass produced by forging.

Because the base material is more malleable at high temperatures, hot forging* is easier to perform. Cold forging requires much greater forces to distort the material to shape, but will be capable of finer finished tolerances and a better surface profile than a hot worked material.

*Hot working can alter the composition of the surface material, e.g. if not controlled may result in high percentage carbon steel with a reduced carbon content effecting any resultant heat treatment processes.

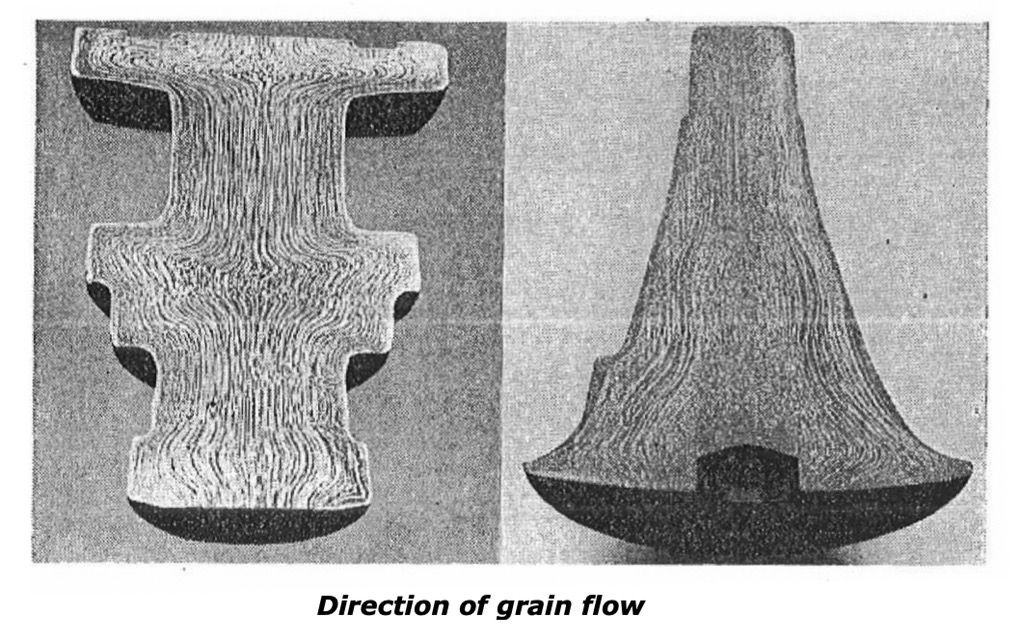

Forging refines the grain structure and improves physical properties of the metal. With proper design, the grain flow can be orientated to take account of the direction of principal stresses encountered in actual use. Grain flow is the direction of the pattern that the crystals take during plastic deformation. Physical properties (such as strength, ductility and toughness) are much better in a forging than in the base metal, which has crystals randomly orientated.

In order to make hollow items it may be required to pierce a solid forged block. This is achieved by forcing a punch through the blank. The end product may be a flat item such as a gear blank, a large diameter ring or a length of tubing. To control the inner diameter of items either an internal roll (rings) or mandrel is used.

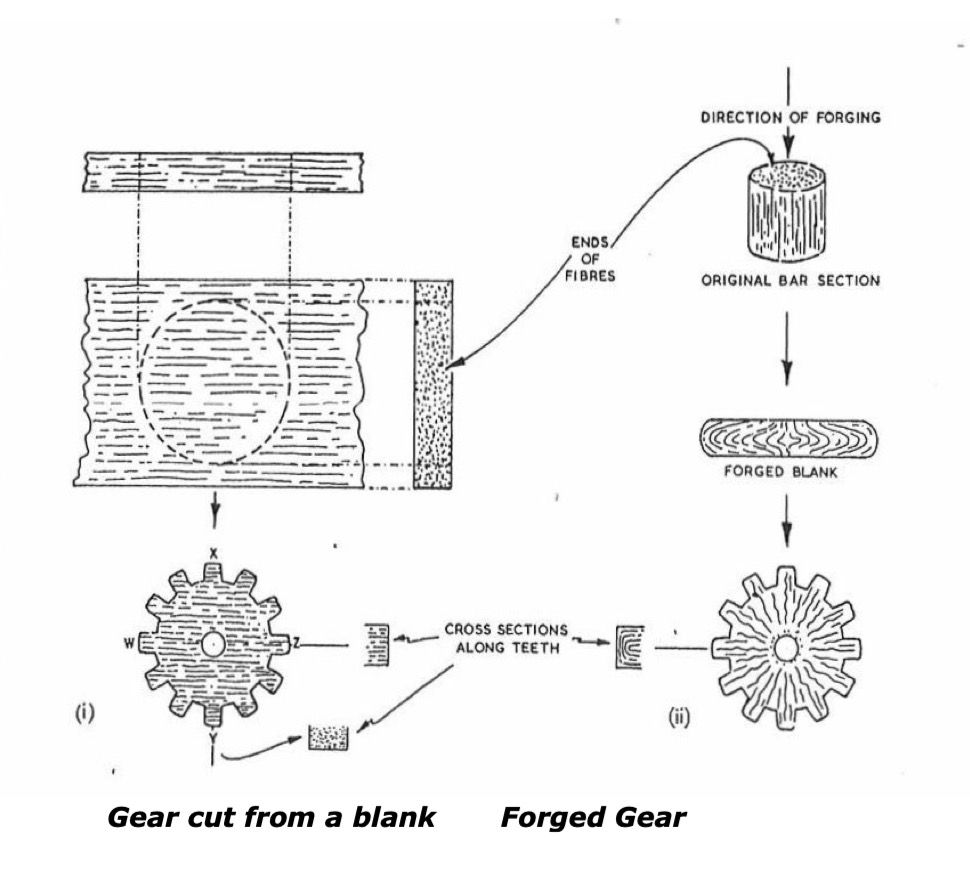

Although more complicated and expensive than cutting from plate (gear blanks and rings) or rolling and welding plate (tubing), forging offers control of fibre flow and thus directional strength.

A gear blank cut from plate would have weak planes in line with the plate olling direction, whereas a forged gear blank would have the strong planes radiating from the centre giving maximum strength and toughness in the essential plane.